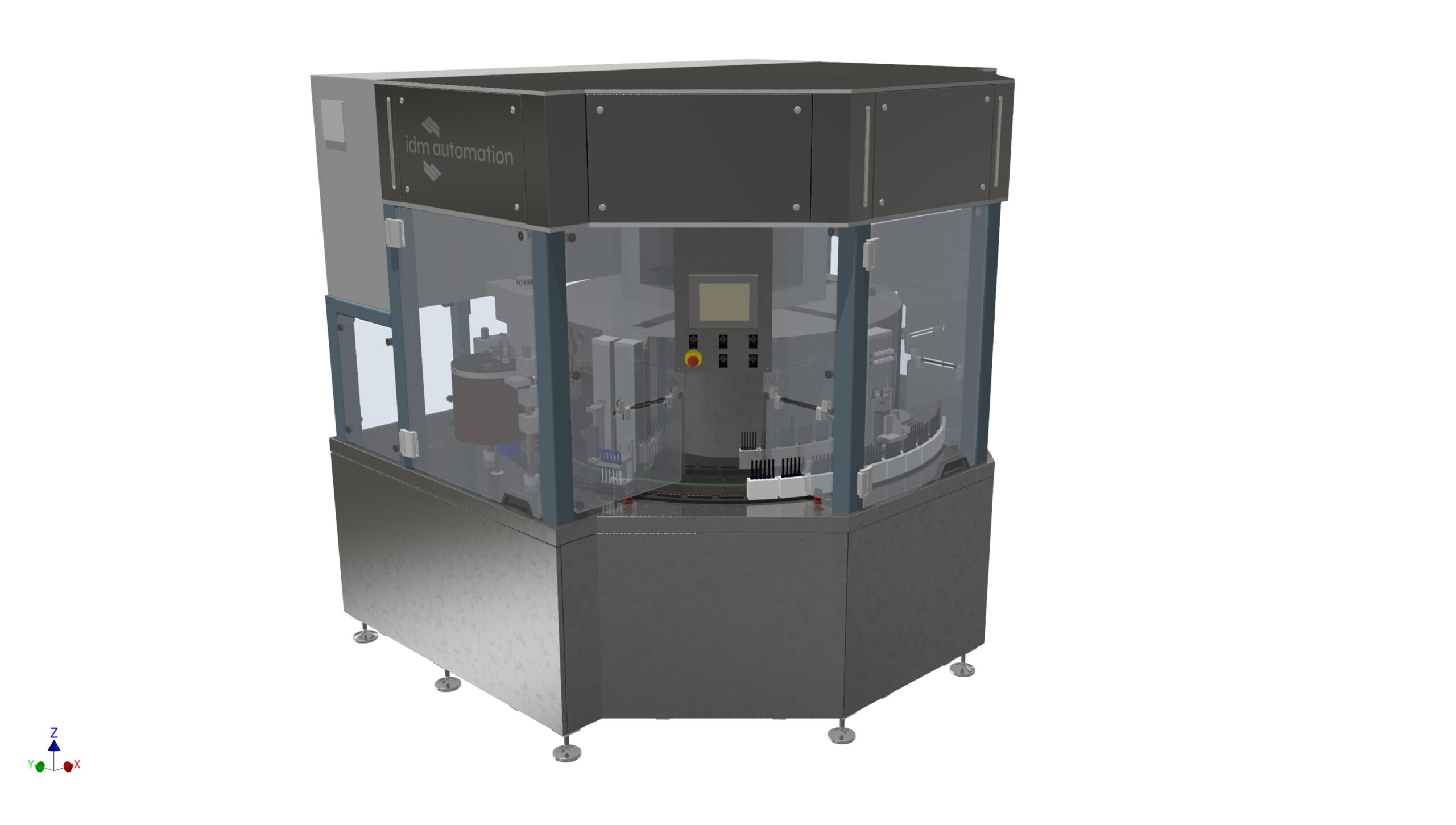

Semiautomatic technological solution intended to produce hot-cast leads in metal molds and subsequent assembly with the body – pencils. The machinery is equipped with a 50-position rotary table and metal molds, optimized for handling hot-cast leads. The molds are equipped with an integrated liquid thermal exchange system for efficient temperature regulation during production.

Penciltech Fusion MPC-6-050 is compatible with precision dosing of mixtures with different features, and it can be customized and configured by adding the modules required for the production and the degree of automation required

Technical Specifications

- Maximum productivity: 2000 pcs/h

- Supported Format: ⌀ 3 mm – ⌀ 6 mm

Why Choose the Penciltech Fusion MPC-6-050?

- Precision Metering: Extreme accuracy for optimal results

Ergonomic Design: Maximum comfort for operators during

processing - Unified Control Interface: Self-diagnostics and easy access

management - Enhanced Accessibility: High visibility of the product, simplifying

maintenance and cleaning - Guaranteed Security: 5 mm + 5 mm toughened and laminated

glass for safety - Robust Reliability: Low maintenance, long-lasting construction

- Intuitive Control: Simplified management with dedicated

software and operator support

Learn More about our Penciltech Fusion MPC-6-050

Improve your pencil production process with the Penciltech Fusion MPC-6-050. Contact us today for more information or to schedule a personalized consult.